Your Current Location:About Us > Brief Introduction of South Africa Energy Metallurgical Economic Zone

Your Current Location:About Us > Brief Introduction of South Africa Energy Metallurgical Economic Zone

Brief Introduction of South Africa Energy Metallurgical Economic Zone

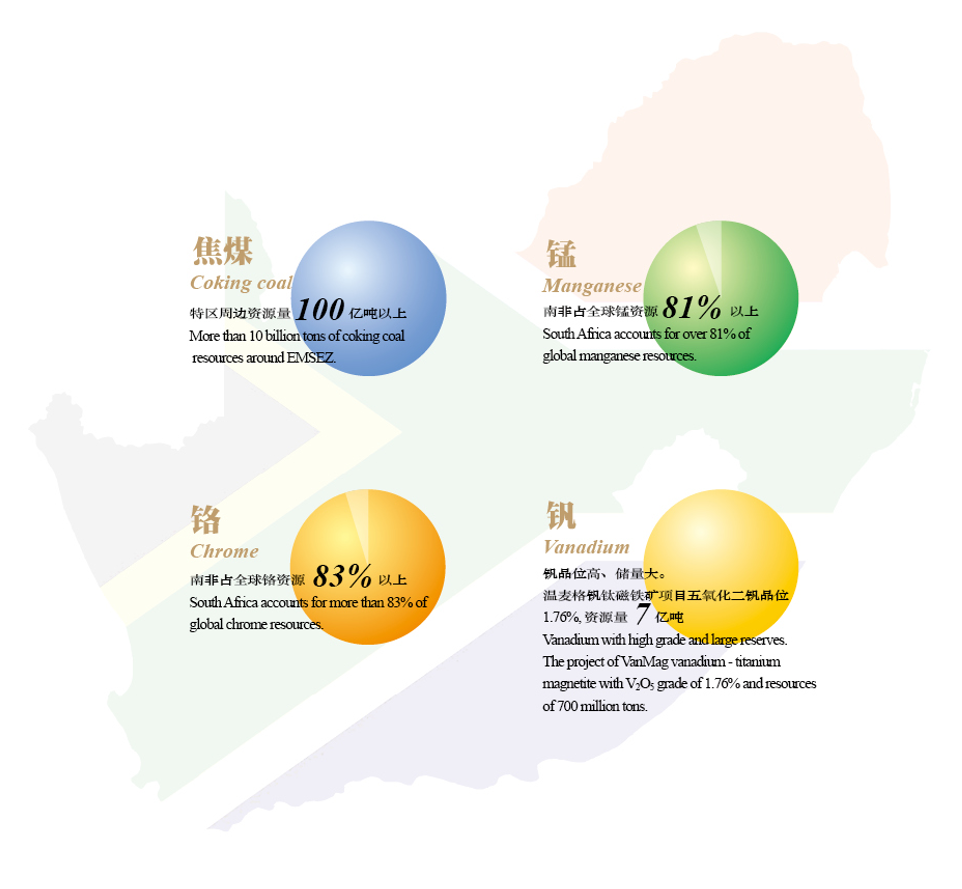

South African Energy Metallurgical Special Economic Zone (hereinafter referred to as EMSEZ or SEZ)is a national level energy metallurgical special economic zone, which was established in accordance with the South Africa's Special Economic Zone Act and approved by the South African government. It enjoys the tax incentive provided to South Africa special economic zones, also enjoys all the preferential treatments in polices that the South African government provided to encourage foreign direct investment. The SEZ Operator Permit was issued by the South African government to the South African Energy Metallurgical Base (Pty) Ltd., for development, operation and management of the SEZ. The SEZ is located in Musina - Makhado, Limpopo province, South Africa, with an area of 60 square kilometers, adjacent to Zimbabwe, Mozambique and Botswana. Around the SEZ there are open pit coking - coal mines, with a deposit of more than 10 billion tons. South Africa has more than 83% of the world' s chrome resource and more than 81% of the world manganese resource, high - grade vanadium resources rank first in the world. There are also other abundant mine resources as raw materials for making stainless steel, such as iron ore, silicon ore, nickel ore and limestone, etc. Through the SEZ run the national railway, highway as well as power supply grid. The SEZ is 500 kilometers away from Port of Maputo, Mozambique. Limpopo River is 30 kilometer away from the SEZ which is the important water source for the SEZ. The following plants shall be constructed under the SEZProject: Coal Washery of 20 Mtpa; Coal - Fired Power Plant of 3,300 MW; Coking Plant of 3 Mtpa with Heat Recovery Power Generation Plant of 390 MW; High - CarbonFerrochrome Plant of 3 Mtpa; Ferromanganese Plant of 1Mtpa; Silicomanganese Plant of 500 Ktpa; Stainless Steel Plant of 3 Mtpa; High - Vanadium Steel Plant of 1 Mtpa and High - Manganese Steel Plant of 1 Mtpa; Metallurgical Lime Plant of 5 Mtpa, Titanium Dioxide Plant of 1.2 Mtpa and Vanadium Pentoxide (V2O5) Plant of 150 Ktpa.

A Mine Resources Supply Center will be established tosupply metallurgical charges mineral resource for the SEZ plants.The energy and metallurgy integration advantage of SEZ Projects: coking coal mine→coal washery→coking plant→power plant→ferroalloy plant→iron making plant→steel making plant, which form a connected sequence of energy and metallurgy production full process flow, with BF hot metal and ferroalloy molten to be hot delivered to the steel making, which will increase the smelting recovery rate and reduce the energy consumption at the same time. The advantage of such energy and metallurgy integration over the entire process is given by its unique nature and will be the only one of its kind. EMSEZ Operator will provide secured and competitive resources supply and offer supporting services for project investors.

Links:

- South African Embassy in China

- Limpopo provincial government

- Limpopo Economic Development Agency

- Chinese Foreign Ministry

- Chinese Embassy in South Africa

- China in South Africa by reference

- South Africa Department of Trade and Industry

- South Africa Ministry of Finance

- South African Internal Revenue Service

- PIC

- China-Africa Fund

- Eskom

- Department of Mineral Resources South Africa

- Department Of Energy South Africa

- Department of Water and Sanitation South Africa